Pump Curve

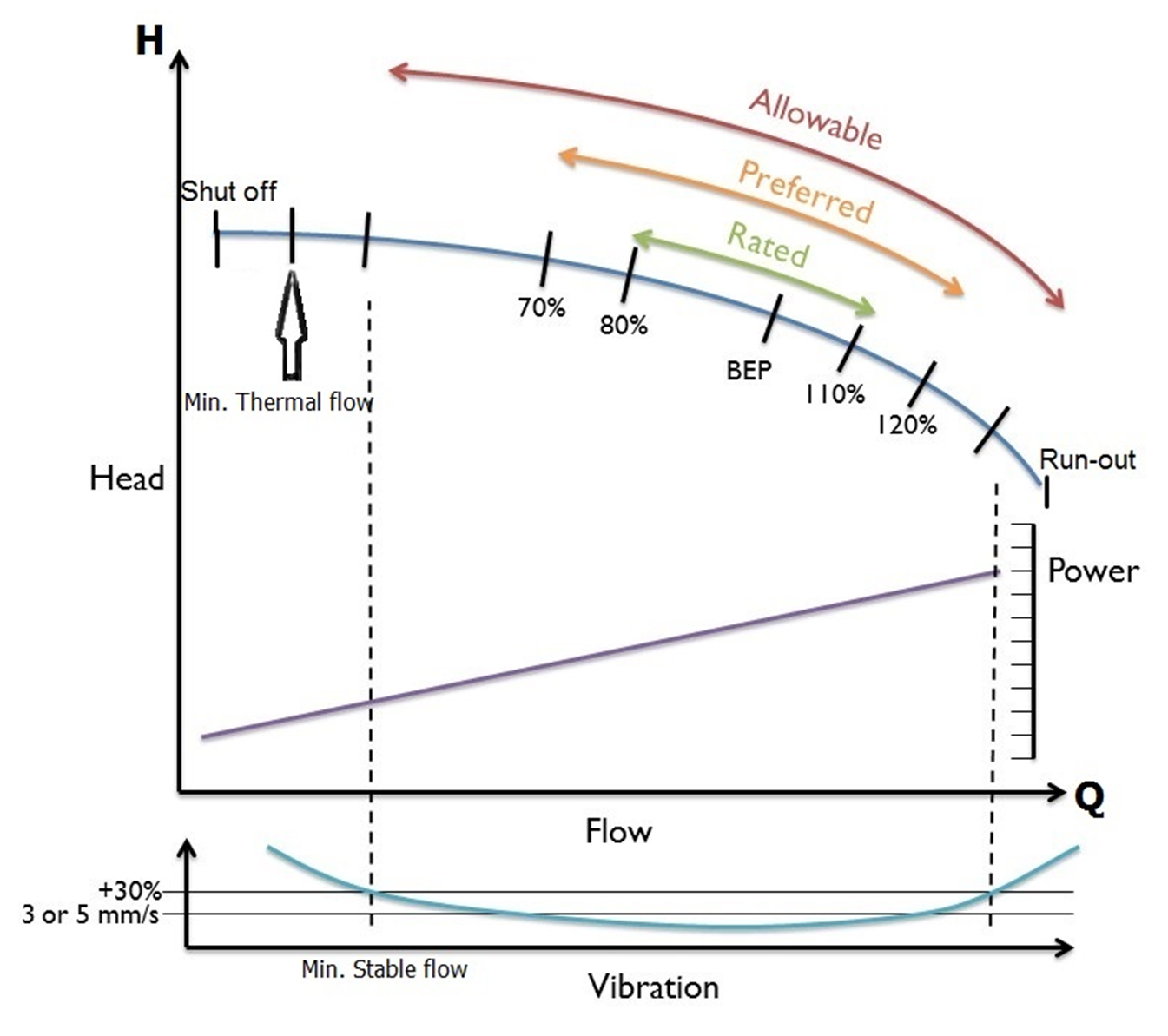

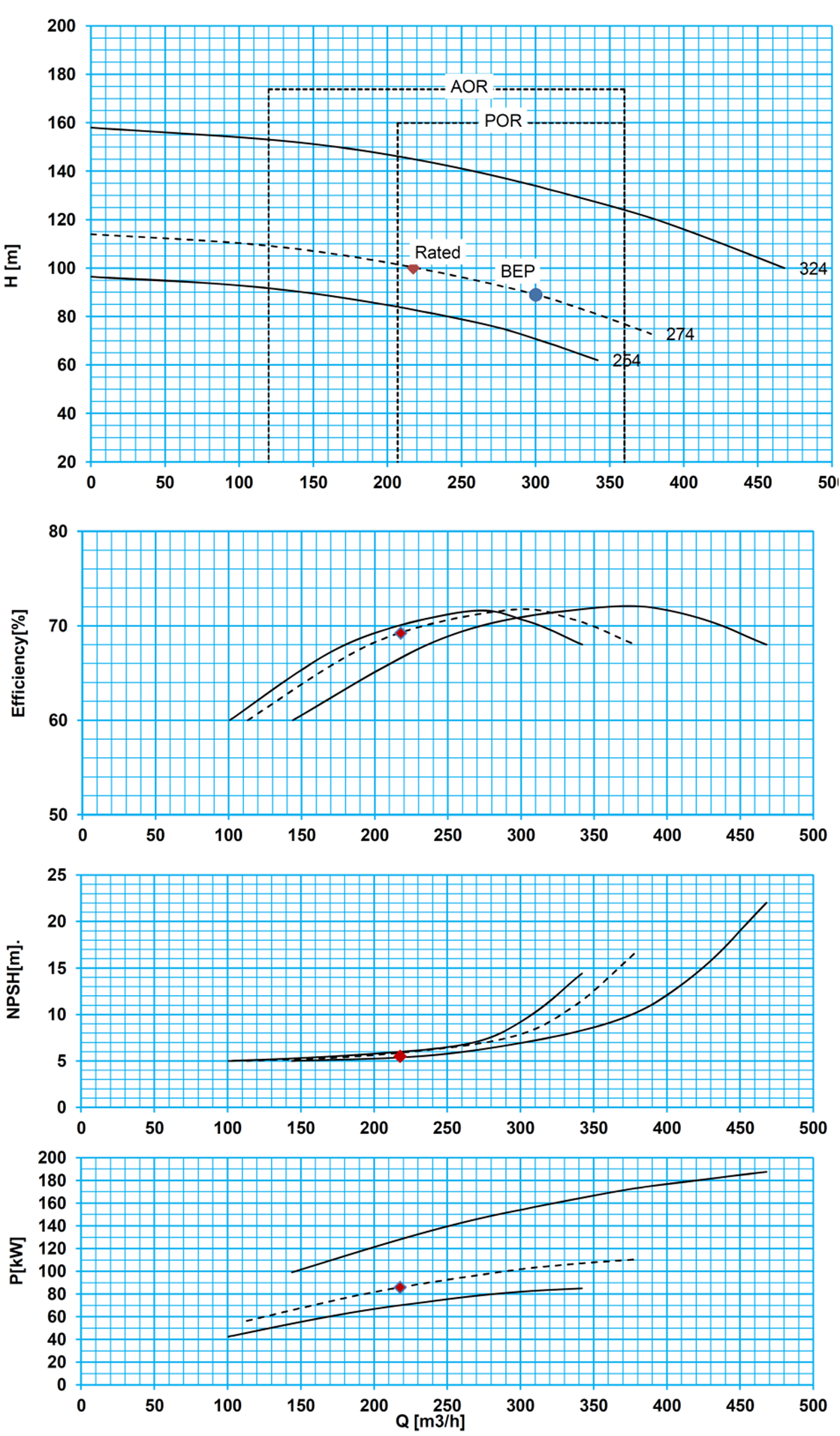

BEP:

A point on pump curve that flowrate at which a pump achieves its highest efficiency at rated impeller diameter.

The best efficiency point flowrate at maximum impeller diameter is used to determine pump specific speed and suction specific speed. The best efficiency point flowrate at reduced impeller diameters is similarly reduced from the value at maximum impeller diameter.

Rated Flow Point:

Normal Flow x 110% = Rated Flow Point

Rated Flow Region:

Rated flow point shall be within the region of 80 % to 110 % of best efficiency flowrate of the pump.

Preferred operating region:

Portion of a pump’s hydraulic coverage over which the pump’s vibration is within the base limit of this International Standard. Pumps shall have a preferred operating region of 70 % to 120 % of best efficiency flowrate of the pump.

Allowable operating region:

Portion of a pump’s hydraulic coverage over which the pump is allowed to operate, based on vibration within the upper limit of this International Standard or temperature rise or other limitation, specified by the manufacturer.

Minimum continuous stable flow:

lowest flow at which the pump can operate without exceeding the vibration limits imposed by this International Standard. The lowest flow point of allowable operating region shows min. stable flow.

Minimum continuous thermal flow:

lowest flow at which the pump can operate without its operation being impaired by the temperature rise of the pumped liquid.

Shut-off Head:

When pump works at no flow and has the highest head (normally at the first of curve), this means, close the valve on pipe line which exists next to the pump. Shutoff point shows the highest point on the pump curve (if pump has stable curve). The shutoff pressure of a typical centrifugal pump is approximately equal to the sum of the maximum suction pressure and 120% of the net differential pressure generated by the pump, based on the maximum anticipated fluid density.

Run out:

When pump works with the highest flow and also the lowest head. Normally it is called end curve.

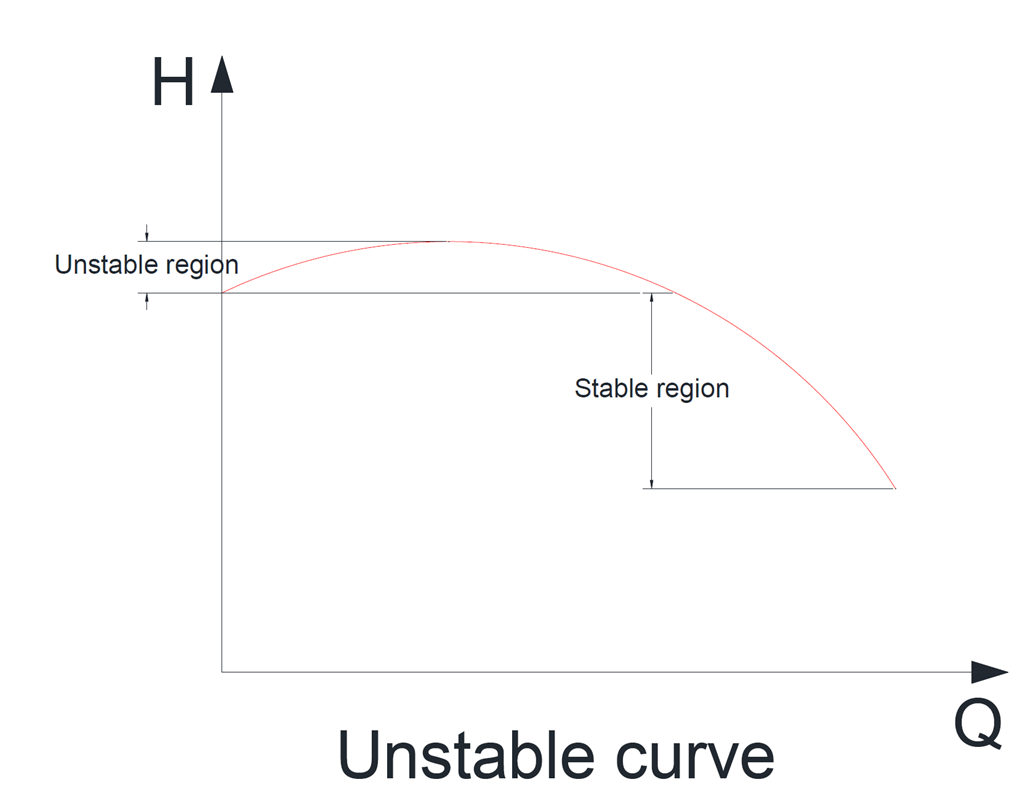

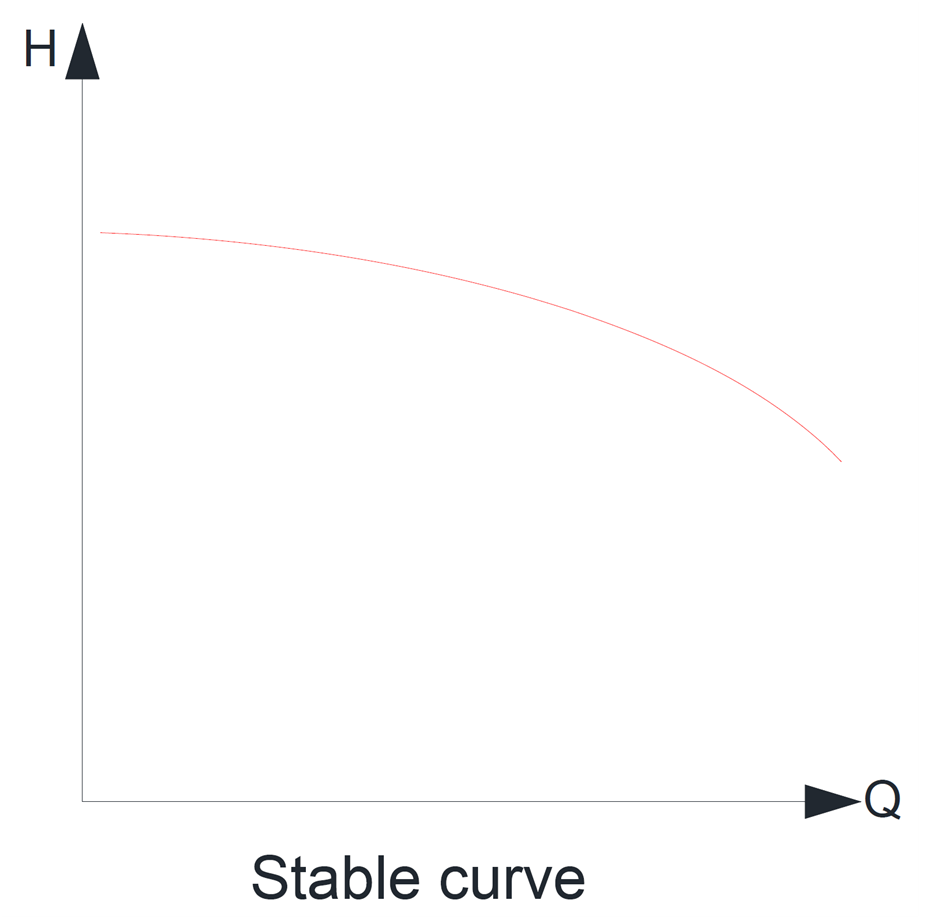

Stable curve:

Pumps that are continues head rise to shutoff, have stable curve.

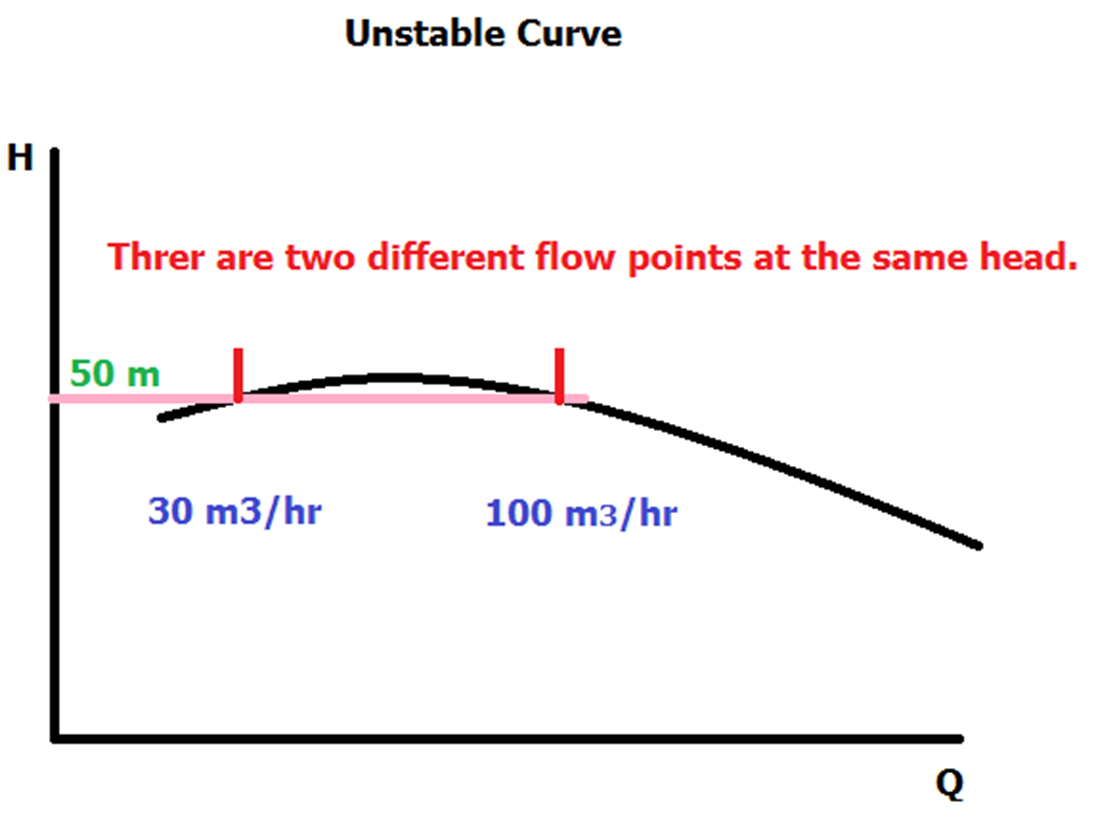

Unstable Curve:

If a pump with a drooping head-capacity curve is operated near the maximum head/flow point, unstable operation may result. The system may experience fluctuations in head and capacity as the pump tries to match the system flow rate and head requirements. Fluctuations in head and capacity are followed by fluctuations in the power and the speed of the unit, which under certain conditions, can induce mechanical vibrations in the piping system.

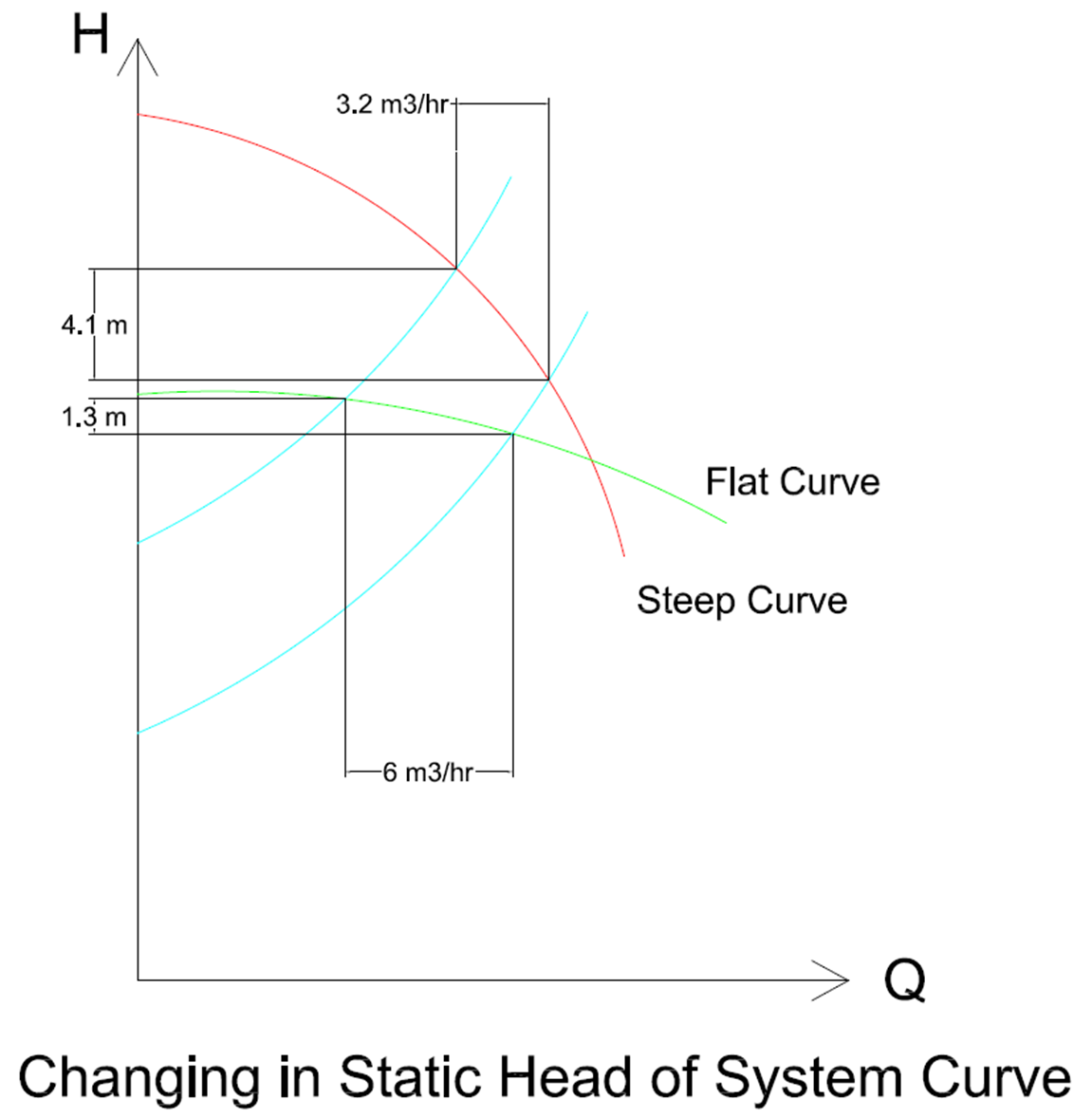

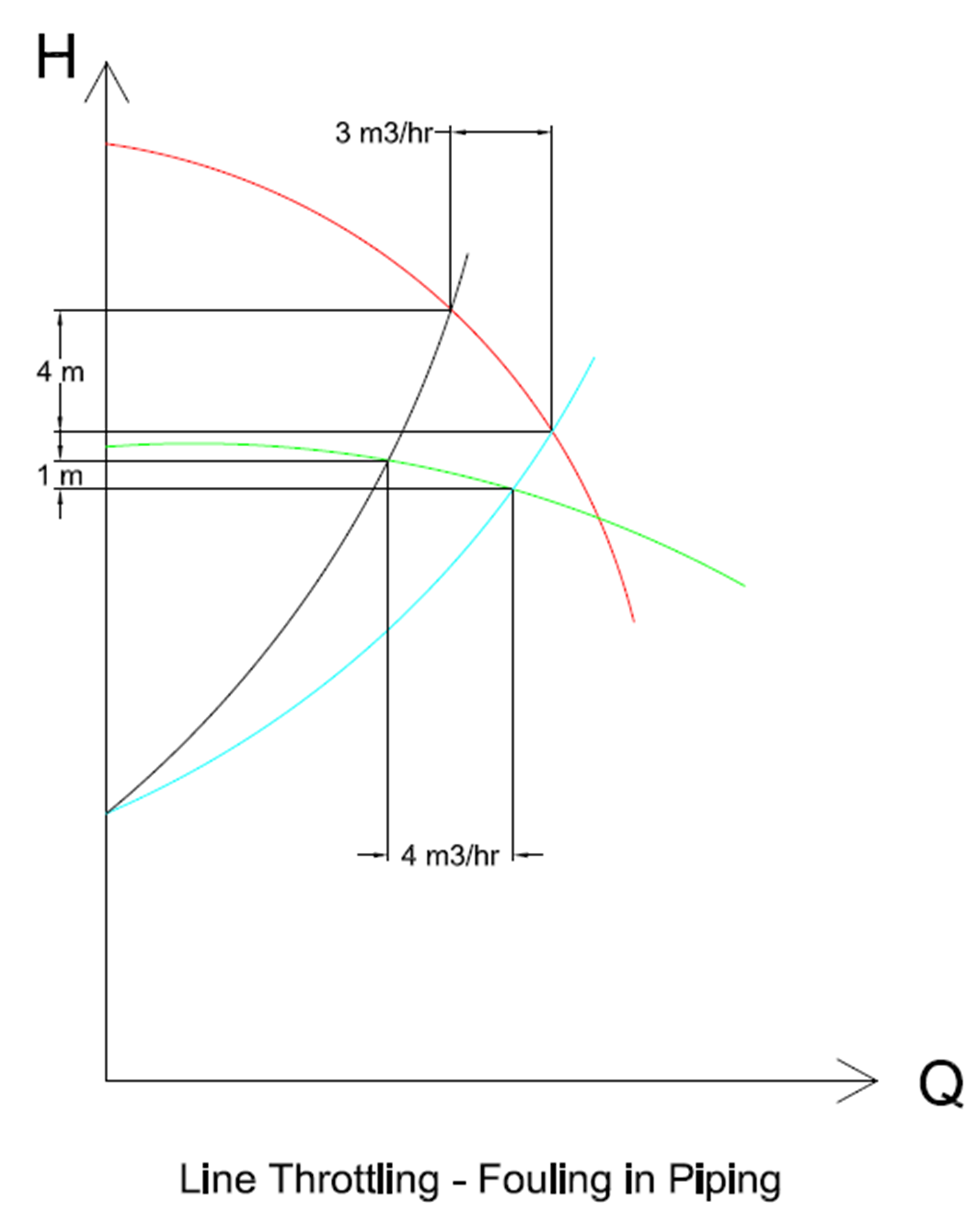

Flat curve:

The rate of increase of head from BEP to Shutoff Head is introduced as Head Rise. If the head rate is less than 10%, we call it a low slope or Flat curve.

Steep curve:

If the head rise is more than 10%, we call these curves steep.

In some cases, it is not recommended to use a low slope curve. For example, in fire water pumps, the pump curve should not have a steep slope.

Also, according to the above two figures, the first figure, if the static head changes, a high head change occurs in the steep curve and a high flow change occurs in the flat curve. In cases where the static head of the system is variable, it is better to use the steep curve for regular delivery flow.

Over time, as the sedimentation of the pipes increases, the dynamic head of the system curve changes and can be seen in the second figure, or by closing the valve after the pump, changes are made in the working point of the pump, which can be seen in Figure 2.

Comments:

- Minimum acceptable diameter shall be at least 80% of the maximum impeller diameter.

- Shut-off head shall be minimum 5% above rated head at rated speed.

- Confirm that the pump subject to parallel operation have 110 to 120% of rated head at shutoff.

- Pumps shall be capable of at least a 5% head increase are rated conditions by replacement of the impeller(s) with one(s) of larger diameter or different hydraulic design, variable-speed capability or use of a blank stage.

- Pumps shall have stable head/flowrate curves (continuous head rise to shutoff). In parallel operation, the head rise from rated point to shutoff shall be at least 10 %. If a discharge orifice is used as a means of providing a continuous rise to shutoff, this use shall be stated in the proposal.

- The pump head at shutoff shall not exceed 120% of the head at the rated capacity point.

- Pumps shall have a preferred operating region of 70 % to 120 % of best efficiency flowrate of the pump.

- Rated flow point shall be within the region of 80 % to 110 % of best efficiency flowrate of the pump.

- Minimum Continuous Stable Flow shall be equal to the lowest point of allowable operating region.

- The best efficiency point for the furnished impeller shall preferably be between the rated point and normal point.