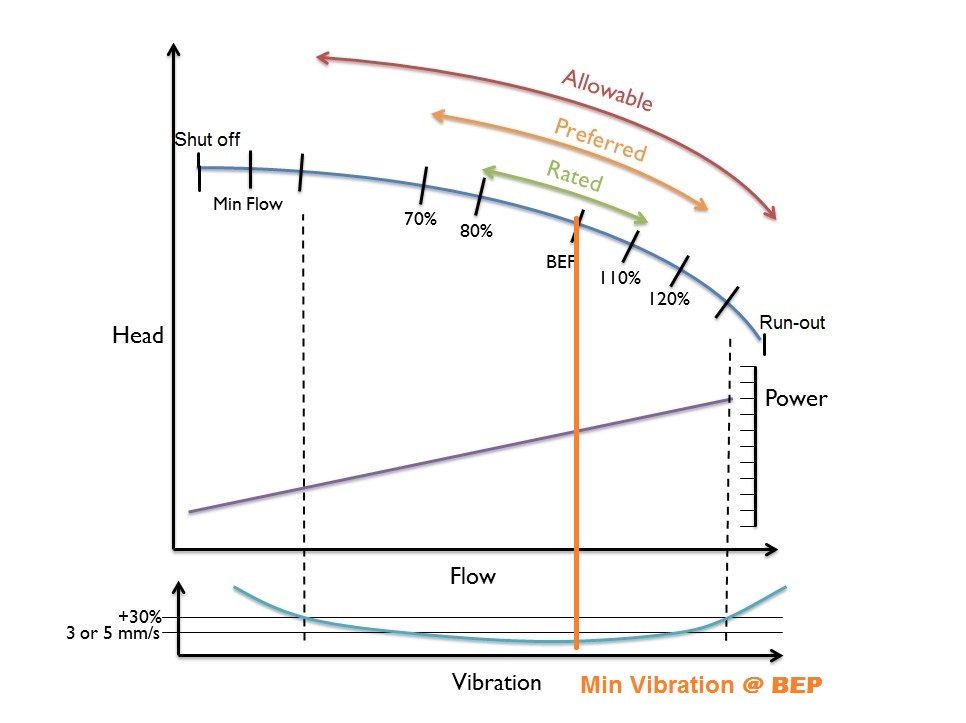

RATED CURVE BEP FLOW (at rated impeller dia):

BEP is a flowrate at which a pump achieves its highest efficiency at rated impeller diameter.

At the BEP, flow enters and leaves the pump with a minimum amount of flow separation,

The best efficiency point (BEP) for most single stage centrifugal pumps is somewhere between 80% and 85% of the shut off head. You are going to have to look at your individual pump curve to get the exact number.

- Too far to the right and you can run out of Net positive suction head available (NPSHA)

- Too far to the left and you can get internal recirculation, heat and vibration

- Begins at 80% – 60% flow

- Severe below 40% – 20%

- API 610 states a minimum 60% standard, 70% preferred and 120% allowable, 110% preferred

- Operating on either side of the BEP will produce undesirable radial forces on the impeller

Unfortunately high efficiency also means higher maintenance costs because:

you are required to maintain tighter tolerances and keep the flow passages smooth and free from obstructions. The demise of the double volute pump design in smaller size pumps is a perfect example of the increase in mechanical seal problems as the efficiency of the volute pump was increased to satisfy consumer demand.

- The normal operating point for the pump shall be between 0 and 10% to the left of the best efficiency point. {Total Spec.}

- 1.13 The best efficiency point flowrate for the pump as furnished should preferably be between the rated point and the normal point. {API 610}

Comments:

- The best efficiency point flowrate for the pump as furnished should preferably be between the rated point and the normal point. {API 610}

- Vendor shall specify Q at BEP for maximum impeller.