Area classification, based on IEC 60079 or API RP 500.

ELECTRIC AREA CLASSIFICATION shall be extracted from Hazardous Area Classification drawing. If such a document is not exist, those data shall be taken from electrical department.

Ambient Temperature (-20°C to +40°C if not marked)

Establish Zone Based on “IEC 60079-10”.

Zone 0 – Explosive atmospheres present continuously long periods or frequently.

Zone 1 – Explosive atmospheres are likely to occur.

Zone 2 – Explosive atmospheres are unlikely to occur or present only infrequently and for a short period only.

Safe Area – Non Ex

The Area Classification

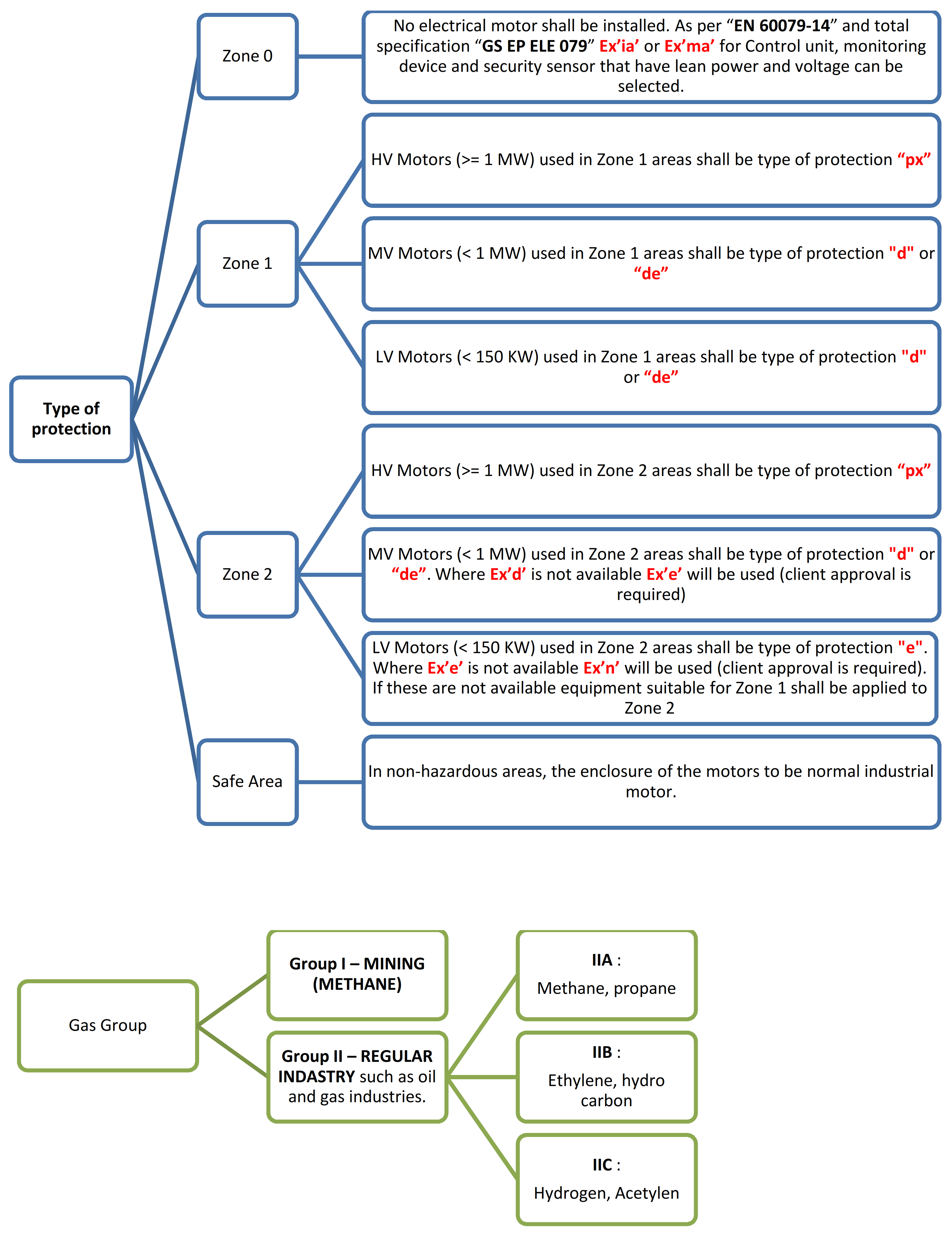

1st Criteria: Ascertain if a gas belongs in Group I or II

Gas Group, There are two main gas groups:

Group I – MINING (METHANE)

Group II – REGULAR INDASTRY such as oil and gas industries.

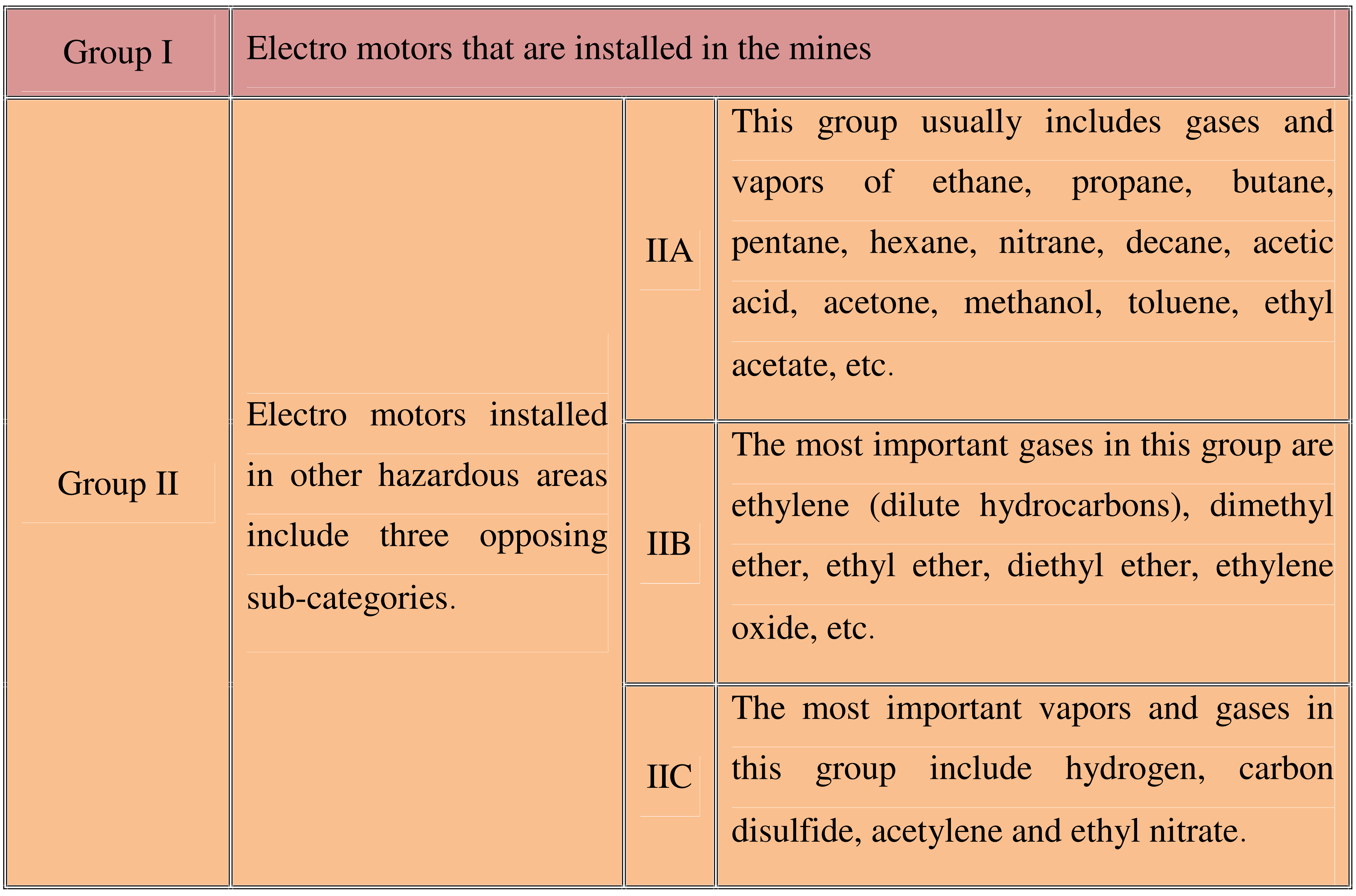

Gas group: Explosion-proof electric motors are divided into two groups depending on their usability in hazardous areas:

Group I: Engines used in mines and in environments where methane or coal dust and other combustible dust are present. The devices in this group have two temperature levels. One is T <150 Cº and the other T <450 Cº which are selected according to the flammable temperature of the particles in the atmosphere.

Group II: Electro-motors that can be used in hydrocarbon areas and spaces where flammable gases are present.

Group II is divided into three subgroups IIC, IIB, IIA according to the type of atmospheric gas. The table below shows the type of gas of each group and its degree of ignition. The maximum surface temperature of the device should be 10% to 20% lower than the gas ignition temperature in the atmosphere.

2nd Criteria: Determine type of gas subdivision (see following pages for breakdown of all gas types)

A – Hydrocarbons, Oxygen, Halogen, Sulfur, and Nitrogen (less explosive concentrations and types)

B – Hydrocarbons, Oxygen, Halogen, Sulfur, and Nitrogen (more explosive concentrations and types)

C – Acetylene, hydrogen, carbon disulfide. Electrical equipment in batteries room shall be apparatus group IIC {Total spec. GS EP ELE 079}.

3rd Criteria: Establish Zone. Based on “IEC 60079-10”.

Zone 0 – Explosive atmospheres present continuously long periods or frequently.

Zone 1 – Explosive atmospheres are likely to occur.

Zone 2 – Explosive atmospheres are unlikely to occur or present only infrequently and for a short period only.

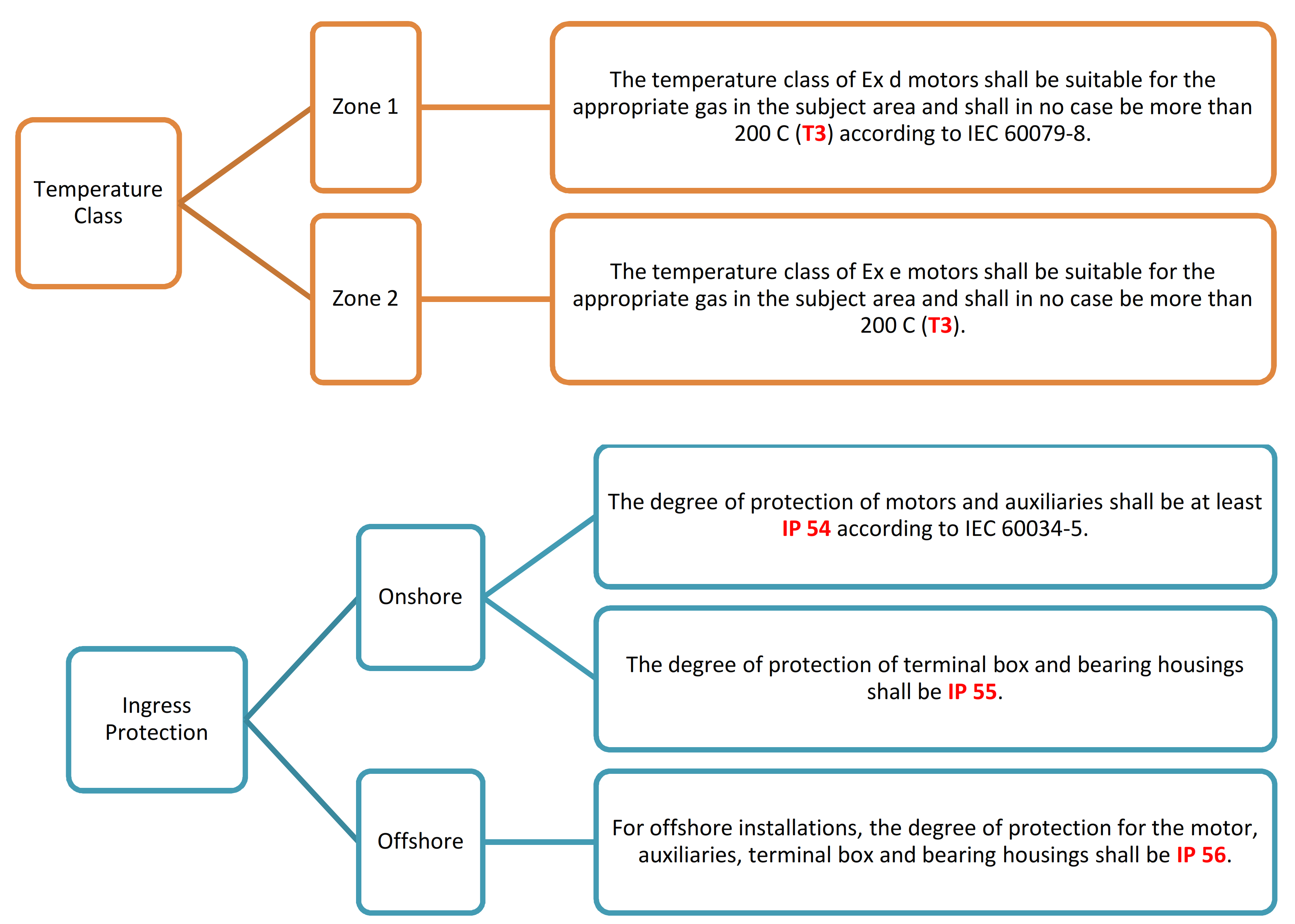

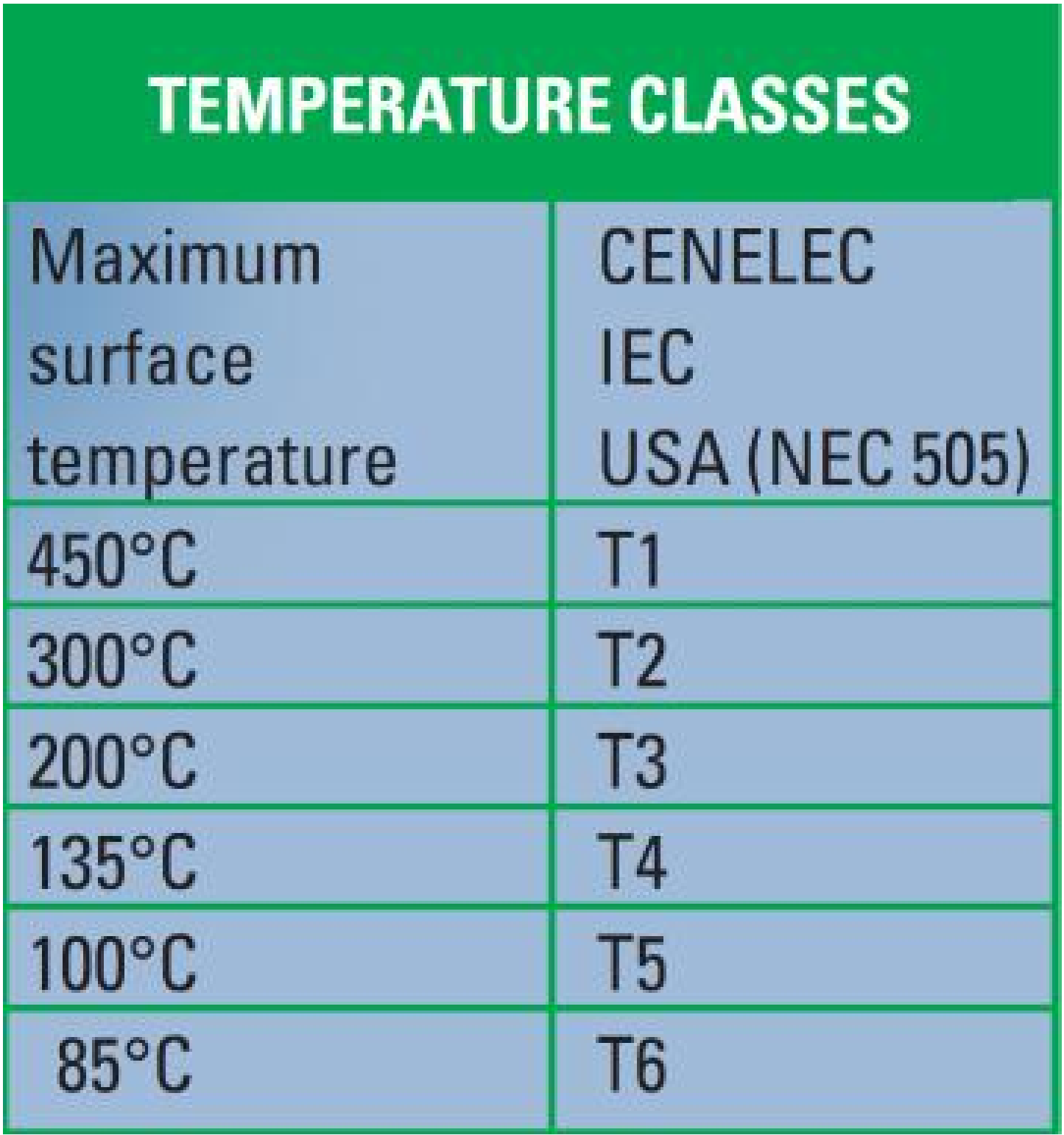

4th Criteria: Temperature Rating:

Hot surfaces can ignite explosive atmospheres. To guard against this all Electrical Equipment intended for use in a potentially explosive atmosphere is classified according to the maximum surface temperature it will reach in service. This temperature is normally based on a surrounding ambient temperature of 40 degrees Centigrade.

For Zone 1: The temperature class of Ex d motors shall be suitable for the appropriate gas in the subject area and shall in no case be more than 200 C (T3) according to IEC 60079-8.

For Zone 2: The temperature class of Ex e motors shall be suitable for the appropriate gas in the subject area and shall in no case be more than 200 C (T3).

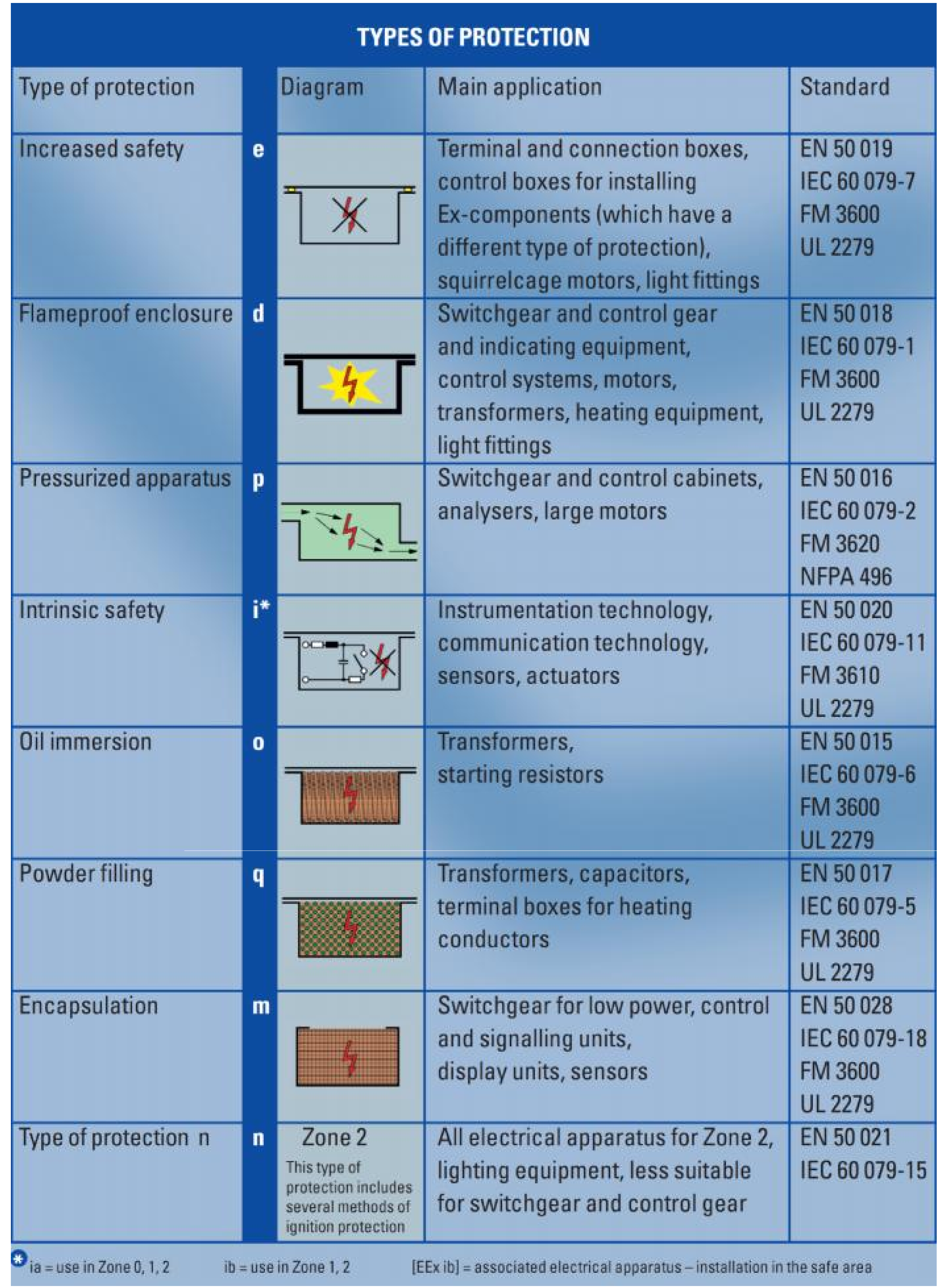

Enclosure type or type of protection: “IEC 60079-14”

Please note that IEC is an international standard that shows enclosure type with Ex symbol and EN (CENELEC) standard is an European standard that shows enclosure type with EEx symbol.

EEx This can be broken down as follows:

E: European certificate in accordance with harmonised standards.

Ex: Explosion-proof electrical equipment

- In hazardous areas classified as zone 0 no electrical motor shall be installed. As per “EN 60079-14” and total specification “GS EP ELE 079” Ex’ia’ or Ex’ma’ for Control unit, monitoring device and security sensor that have lean power and voltage can be selected.

- HV Motors (>= 1 MW) used in Zone 1 areas shall be type of protection “px”.

- HV Motors (>= 1 MW) used in Zone 2 areas shall be type of protection “px”.

- MV Motors (< 1 MW) used in Zone 1 areas shall be type of protection “d” or “de”.

- MV Motors (< 1 MW) used in Zone 2 areas shall be type of protection “d” or “de”. Where Ex’d’ is not available Ex’e’ will be used (client approval is required).

Point: “de” means either motor and terminal box are Ex

- LV Motors (< 150 KW) used in Zone 1 areas shall be type of protection “d” or “de”.

- LV Motors (< 150 KW) used in Zone 2 areas shall be type of protection “e”. Where Ex’e’ is not available Ex’n’ will be used (client approval is required). If these are not available equipment suitable for Zone 1 shall be applied to Zone 2.

- In non-hazardous areas, the enclosure of the motors shall be normal industrial motor.

Stronger protection are respectively as follows:

Ex’de’ > Ex’d’ > Ex’p’ > Ex’e’ > Ex’n’

Note: Terminal boxes for Ex motors shall be minimum with the same protection degree as the motor itself.

Ex d: In these explosion-proof motors, if spark or ignition occurs, it will not propagate outside the electric motor and will not cause combustion in the environment. These motors have a thick cover and shell and weigh more than other similar anti-explosive models. These motors are used in Zone 1 and dangerous explosive areas.

Ex de: Indicates that in addition to the electric motor, the terminal is also explosive and has higher security.

Ex p: In these explosion-proof electric motors, the indoor motors are pressurized by air or an inert gas, thereby removing the atmosphere inside the motor from the external atmosphere and reducing or preventing the possibility of explosion in the outdoor environment. These motors can be used in Zone 1.

Ex n: These motors are also called anti-ignition motors and have been made to ensure that no ignition is ignited when operating under normal and abnormal conditions. Explosive Degree Explosion of Exn is lower than Exd and uses in Zone 2 and is not used in Zone 1.

Ex e: Similar to Exn motors, more stringent measures have been taken to improve their working conditions and are also applicable in the field, but are also used in certain situations in Zone 1.

Certificate of conformity shall be supplied for all Ex type motors. The certificate number and certifying authority shall be indicated in data sheet at quotation stage.

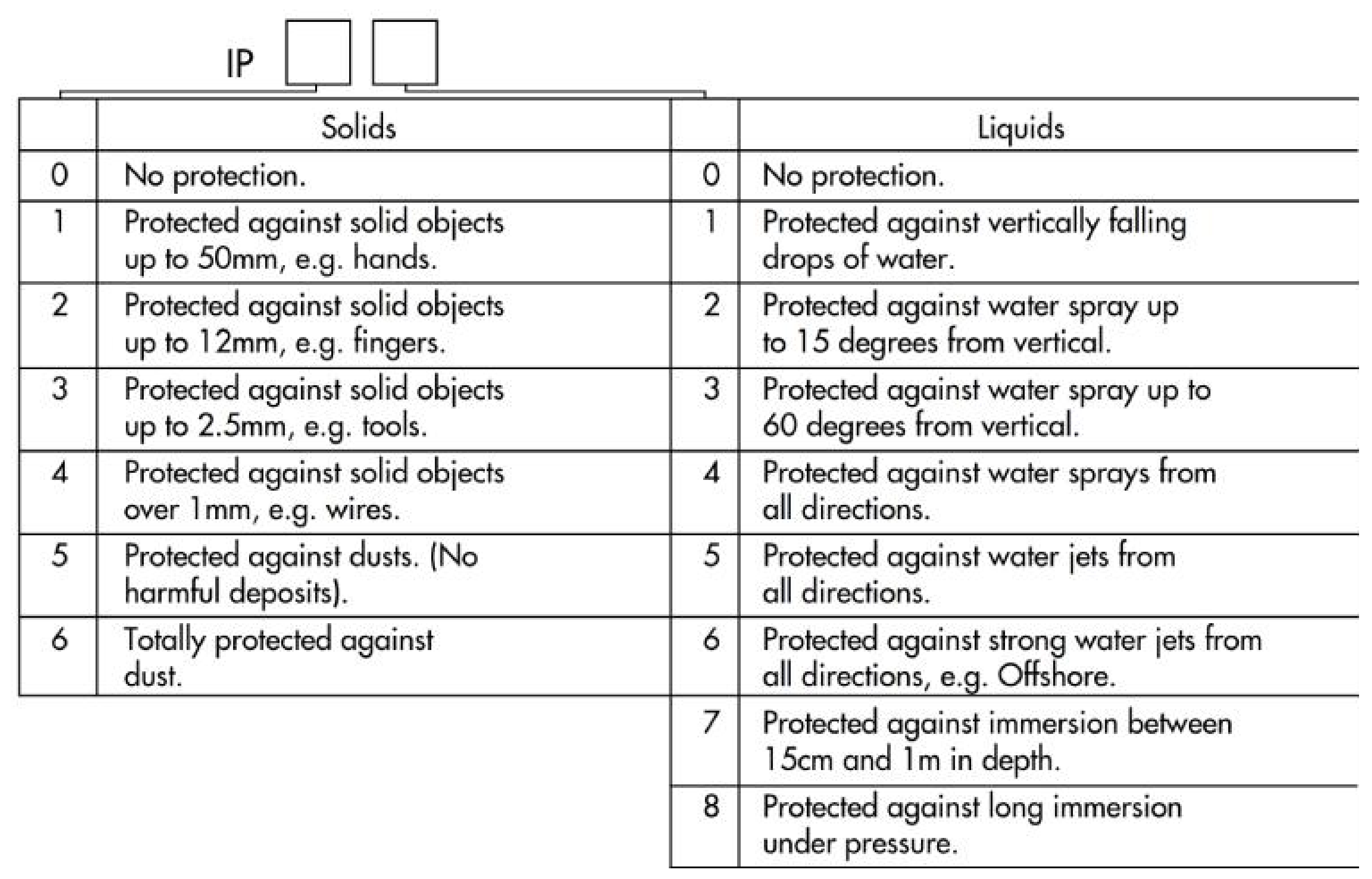

Ingress Protection

2 digits are used to denote the level of ingress protection that a piece of apparatus enjoys: