IMPELLER DIA. Rated Max. Min.

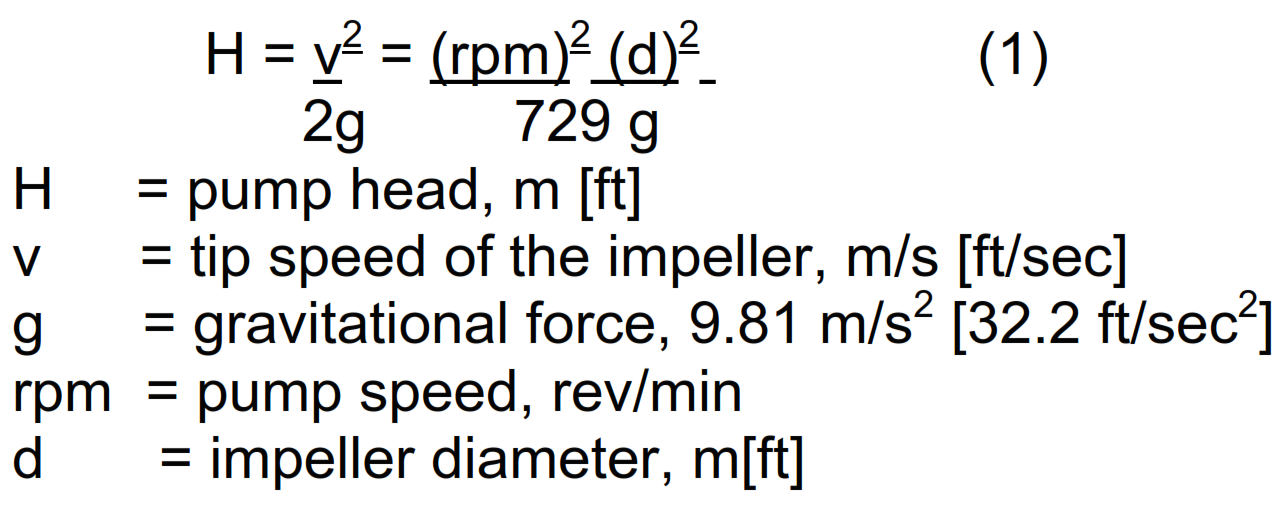

You will probably never use equation (1) in pump calculations, but the relationship of head to pump speed and impeller diameter is very important. The pump head increases with the square of the pump speed and impeller diameter.

- Flow is proportional to speed and impeller diameter.

- Head is proportional to (speed)2 and (impeller diameter)2

- Power is proportional to (speed)3 and (impeller diameter)3

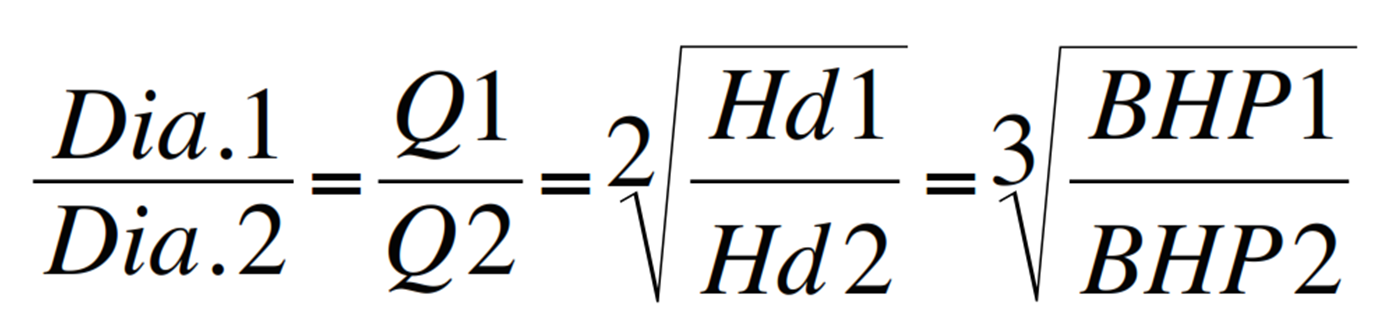

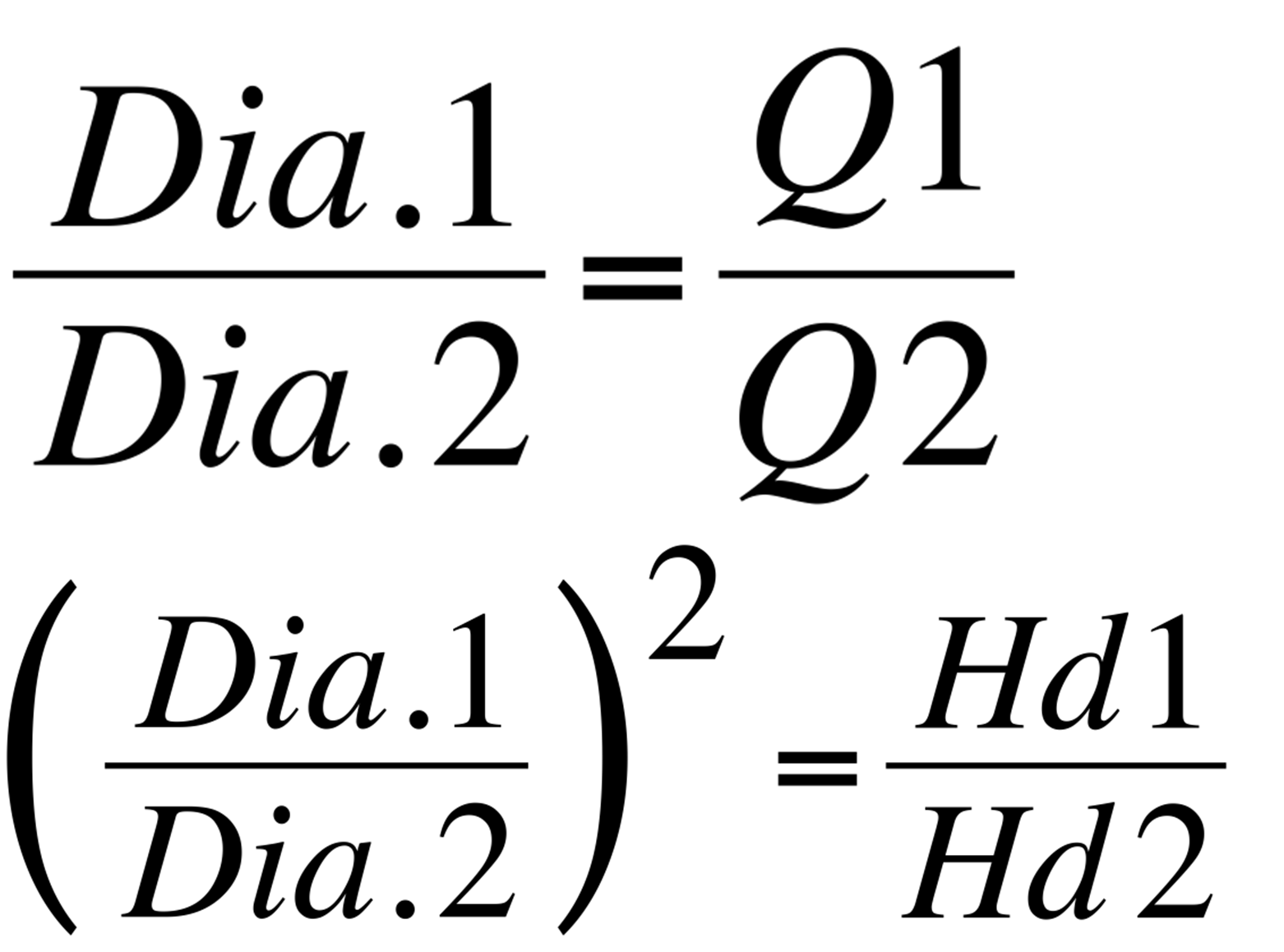

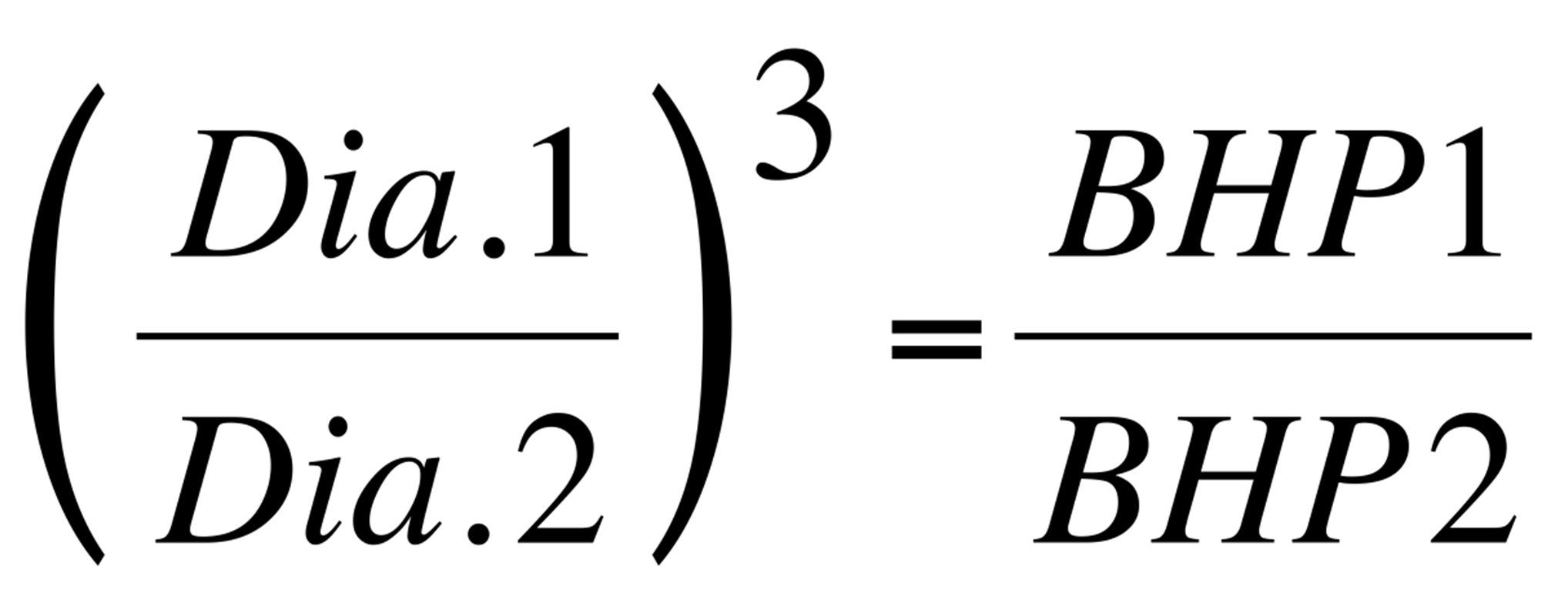

The applicable formula for the change in capacity, head, and horsepower looks the same as those for change in speed.

The relationships are expressed as follows:

-For a given pump and speed:

or expressed in a different way:

|

|

The above formulas are acceptable for small changes of impeller diameter, but should not be used when the impeller diameter changes more than 10%. Because when the impeller dia in a pump is changed, the basic relationship between the impeller and the casing is altered. Thus the design configuration is also changed.

Note: The answers obtained from the calculations are not accurate enough to select an actual impeller dia without first checking the rating curves to determine if the pump has been tested with that particular impeller dia.

Comments:

- Single stage pump with an impeller 500 mm or more running at speeds over 1500 rpm shall be mounted between bearings. (Kermanshah Spec.)

- Impeller diameters shall be 410 mm (16 in) or less for single stage, overhung pumps operating above 1500 rpm. (Kermanshah Spec.)

- The proposed rated impeller dia for pumps with constant speed drivers shall not be greater than 95% or less than 80% of the maximum impeller dia that can be installed in the pump casing. (Total Spec.) (Minimum acceptable diameter shall not be less than 80% of the maximum impeller dia.)

- For pumps with variable speed drives, the impeller dia giving the maximum efficiency shall be selected. If this results in the selected impeller dia being the maximum for the chosen casing, then the driver and pump shall be capable of the speed increase necessary to give a 5% increase in head (per API Std 610 clause 5.1.6 Note) and to correct any head shortfall during testing, including the -2% tolerance per table 14. (Total Spec.)

- For overhung impellers the tip speed of the selected impeller, at the rated operating point, shall not exceed 62 m/s. (Total Spec.)

2 Comments. Leave new

the right hand side of eq. 1 seems to be wrong. The correct form is H=(91.19/8) x (rest of parameters)

I am sorry, the eq. 1 is correct. I made a mistake.